| |

| Welcome to our Little Corner of the Web! | Your browser can't find the .css style script |

| Home | Kid's Stuff | Carol's Stuff | House Projects | Contacts | Our Links | About Us | |

|

Our search for a motor wasn't going too good.

We thought we might have to buy a new one,

and the cheapest we could find was $300 bucks for just a 6 HP. This

didn't look good, as our target is under $500 bucks

During our web search, we ran into people that use old motorcycles for motors and parts. Hey...great idea! Now try to find one! After checking with almost everyone in the state for used bike, ATVs or anything with a small motor. |

|

We ran across a chance deal at a towing

yard my dad deals with. They had 2 wrecks that we scored for a $100

bucks. The motors looked okay, and they had some frame damage, so we took

a chance!

Neither motor was seized and they both had

less than 7,000 miles on them. So after a few hours with the cutting

torch, we have a motor and some parts.

|

|

|

Our first order of business after the torch

was to make the wheel hubs. These new are about $30 each and we need 4.

So off to NAB fabrication, out local fab shop to see Neil and beg for some scrap. Here we laid out the holes and the diameters to cut to. Now to make it round! |

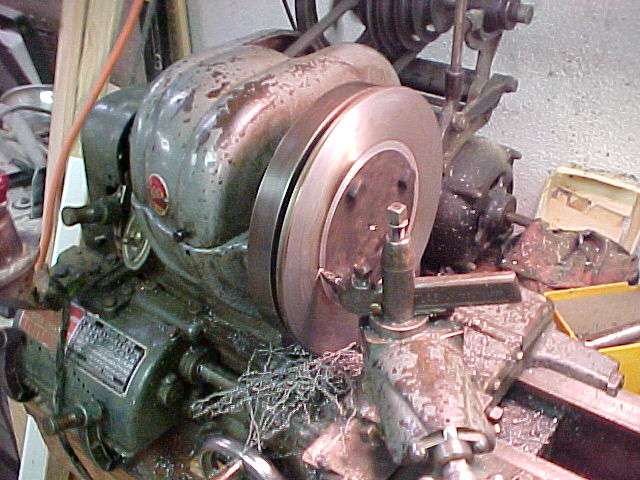

| We mounted the square plate steel onto a lathe faceplate with 4 bolts. We used the tailstock centerpoint pushed against the centerpunch in the plate to hold the alignment while we snugged the bolts. |  |

|

We had to play with the speed to get it right, but after a few minutes we cut through the 3/16" plate |

| Then we cut the center out of the plate and opened the hole to a precise 2.125 inches for the hubs. We had to make 4 plates for the hubs. |  |

|

With a short section of 3" steel we begged from Neil mounted in the 4 jaw check, we faced it square. |

| Then we drilled a small hole inthe center for the axle to pass through. |  |

|

We plan on using a 1" axle shaft, so we had to open it up a little bigger |

|

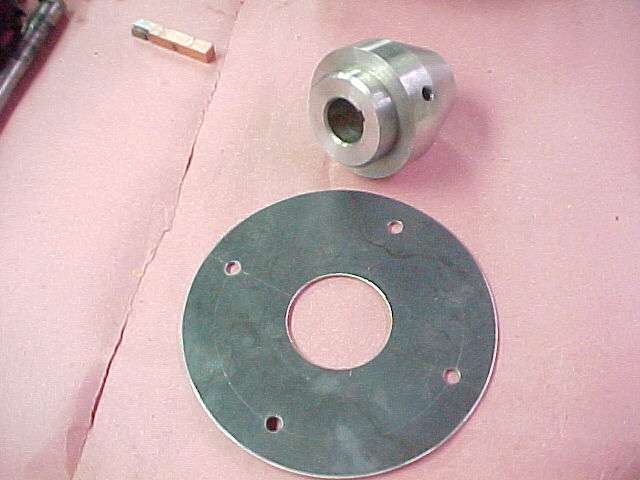

With the ID close to size , we turned the

profile on the outside with a shoulder to locate the plate to.

We cleaned up the OD so we had something to grip when we turned the part around to finish the backside, shown here, we bored the ID to 1.000 inches. We had to buy a broach to make the keyway slots, at work I used a press to push the keyways in all 4 hubs. |

|

|

We don't have a mill (yet?) so we had to

make a fixture to mount in to the lathe cross slide.

This worked pretty good!

We where able to drill all 4 hole right into the keyway slots! Not bad for rookies! |

| Here is the finished hub and plate, you can barely see the key slot, the hole runs right into it. Now we need to weld the 2 pieces together |  |

|

We scored some used tires and rims for $150 bucks from "Slick's Cycle Parts" near Lansing. The hub adapts the wheel to fit the 1" axle shaft. |

|

Both Honda's had drum brakes, and there

is no good way to adapt them over.

We decided on disk brakes, we turned our own rotor from 1/4" plate and found a small to fit. |

|

|

The search for disk brake calipers lead us to Mark, from MGD Construction, he has a ton of stock stuff from his high power street bikes when he upgrades to better stuff. We scored a fine caliper that fit our rotor! |

| We did a mock-up in the garage to get a feel for spacing of components in the frame |  |

|

We had to reverse the direction of rotation of the driveline to get the exhaust to go out the back.

The engine sits on the rear swingarm, and is connected to the rear axle with gears and chains. |

| The frame and axles are coming together |  |

|

Almost a rolling chassis |

| We added upper supports for the frame and suspension |  |

|

back to the top

After our store bought kart was jacked from our barn, we had to replace it with something! This turned out to be a bigger project than planned. We looked at building a kart before we bought one last time, but new parts cost as much as an assembled kart. We hoped to just replace the 5 HP kart that was stolen from our barn, but it evolved into something bigger, a small sand rail. The Honda motors are rated at something like 36HP, so it had to be bigger! The frame went fast, but we're kind of stalled out with the steering and the exhaust. I think I have the steering fixed but I 'll have to fabricate the exhaust pipes and mufflers. Maybe soon we'll hear it start! | |